Skrinex Industrial LLC is formed on the basis of many years of experience in construction, manufacture, design, skills and knowledge implemented in Ukraine. Engineers and construction workers, installers, welders and other specialists carried out a large volume of complex construction, installation works, works on the production of metal structures, piece concrete products (paving slabs, road curb, sidewalk curb, and building blocks).

Skrinex Industrial is formed on the basis of man years of experience in construction, manufacture, design, skills and knowledge implemented in Ukraine. Engineers and construction workers, installers, welders and other specialists carried out a large volume of complex construction, installation works, works on the production of metal structures, piece concrete products (paving slabs, road curb, sidewalk curb, and building blocks)

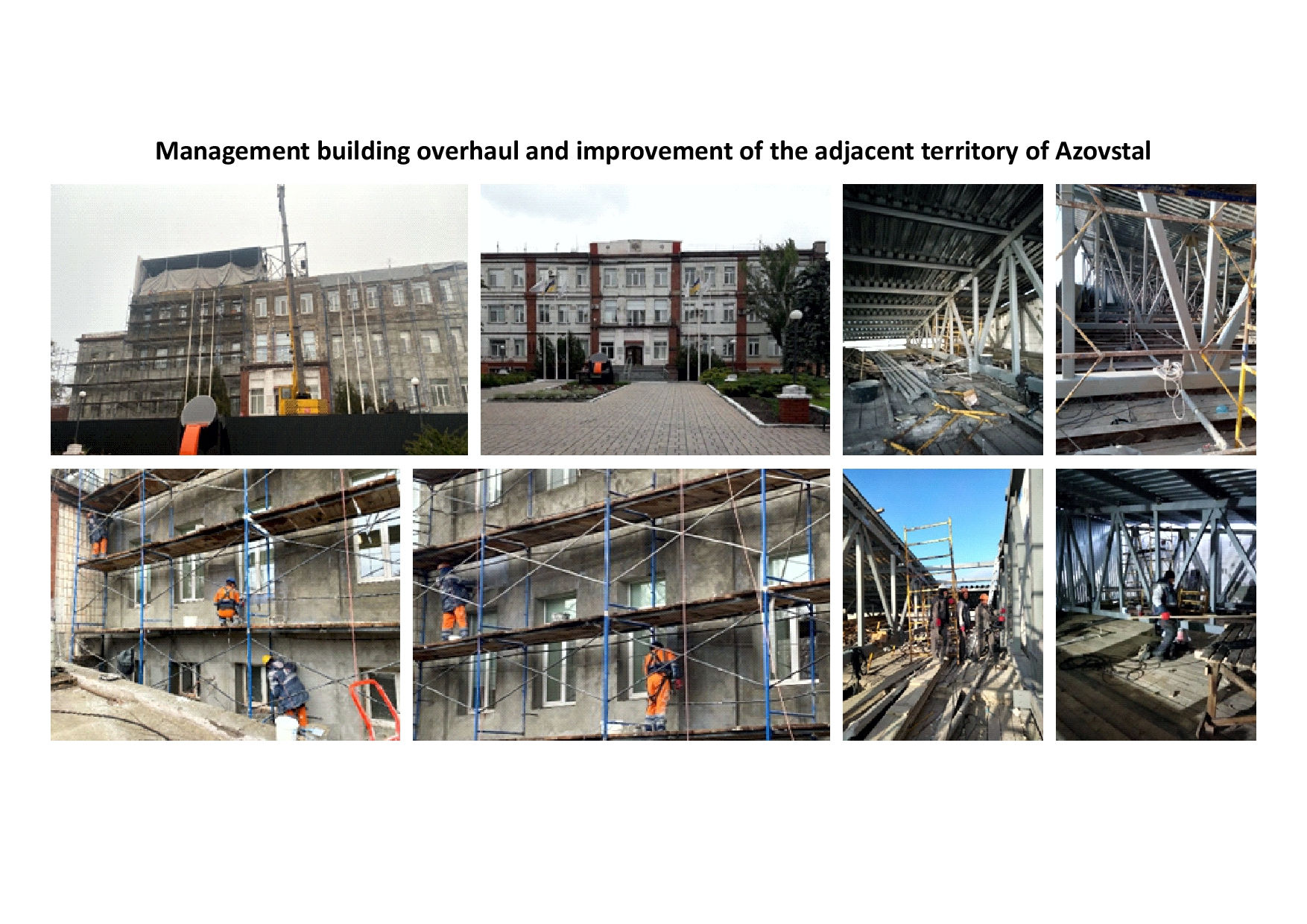

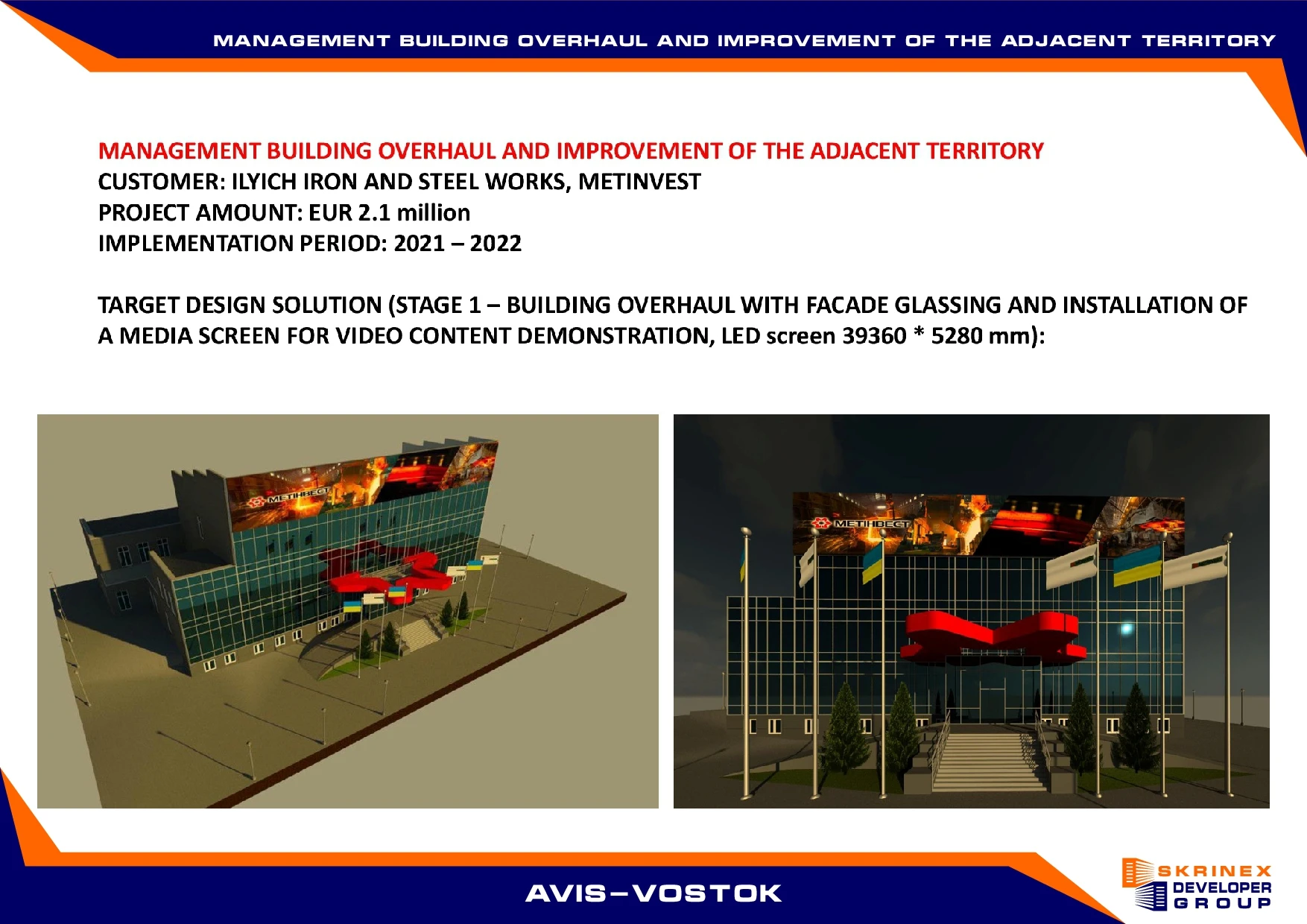

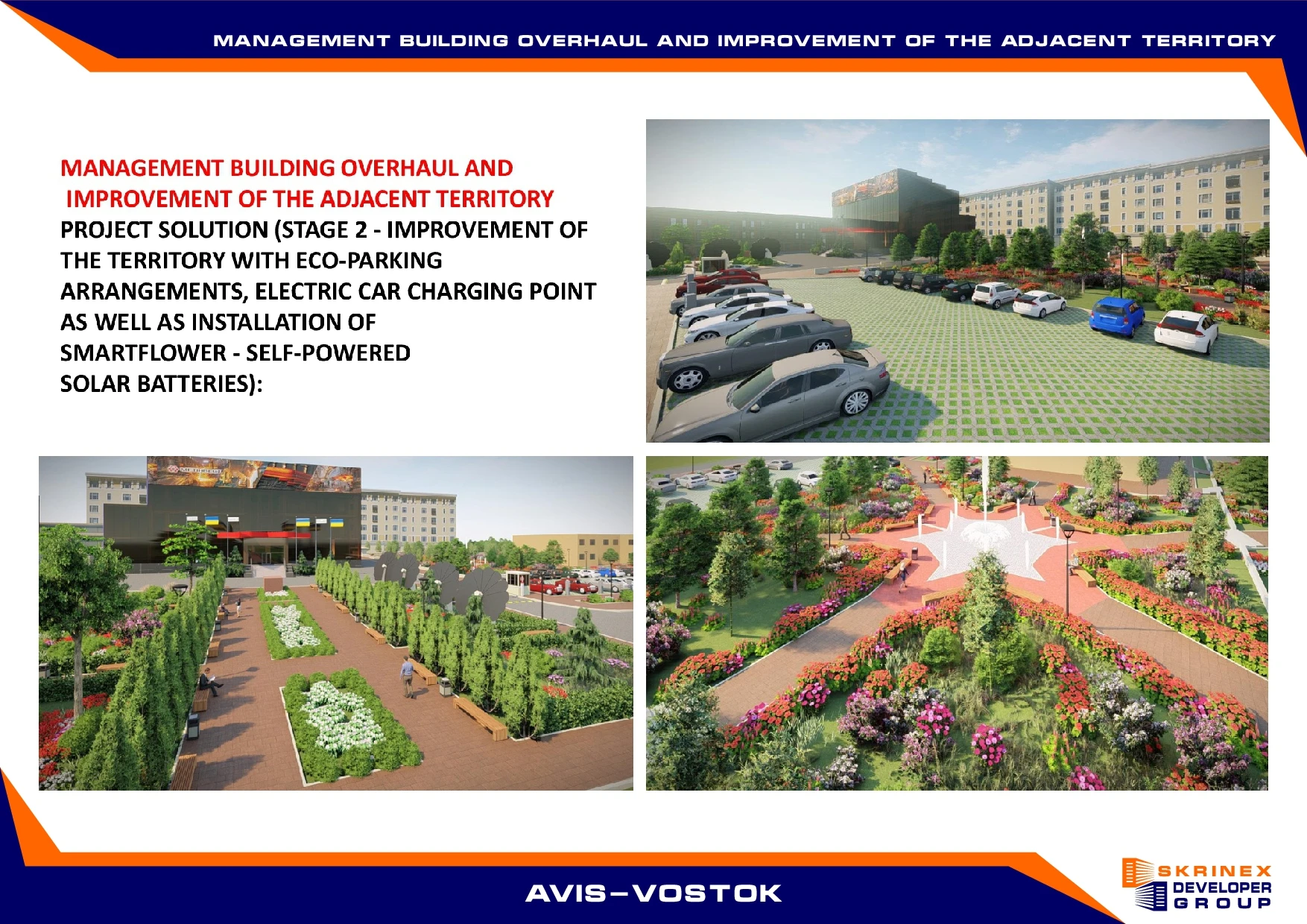

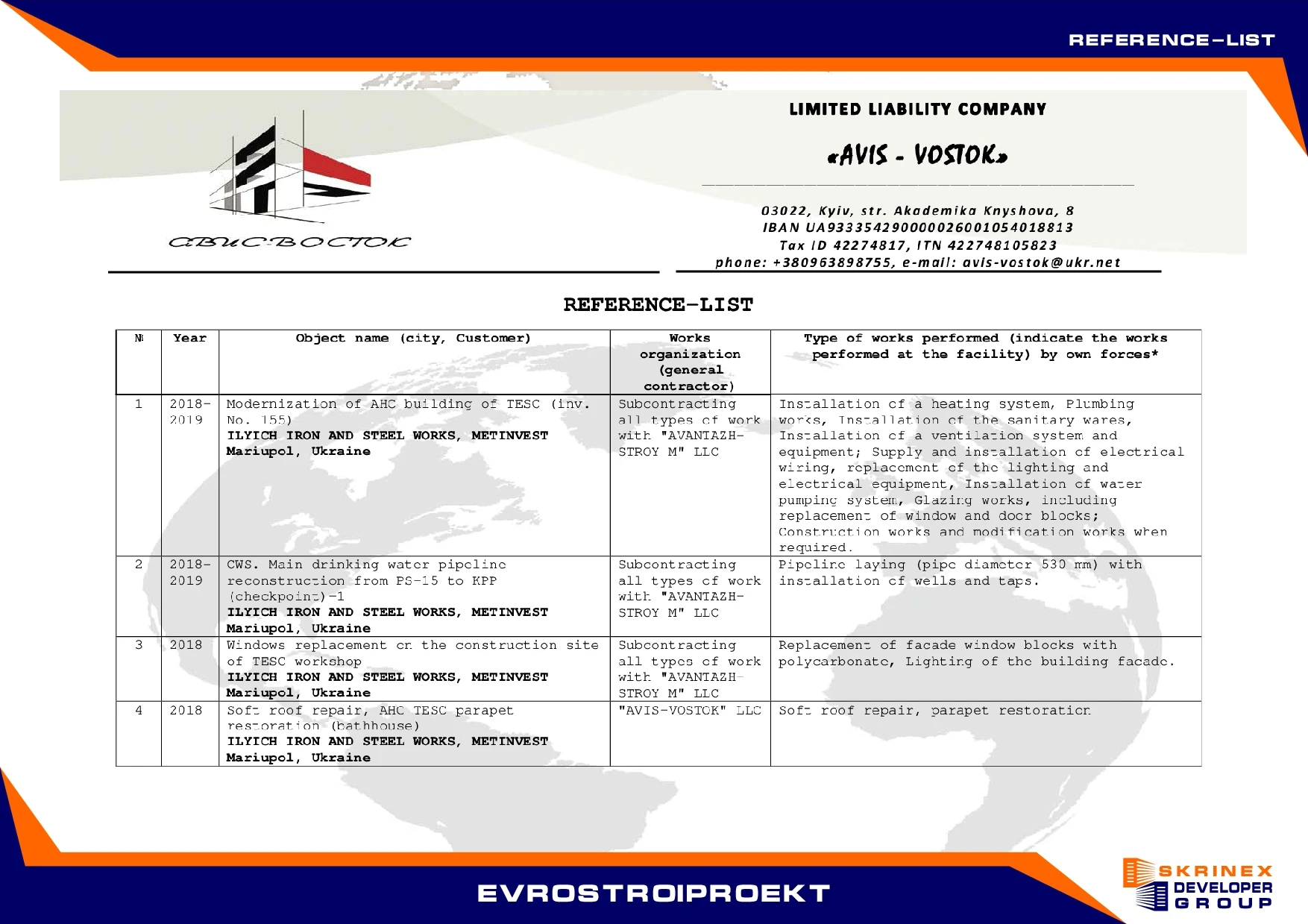

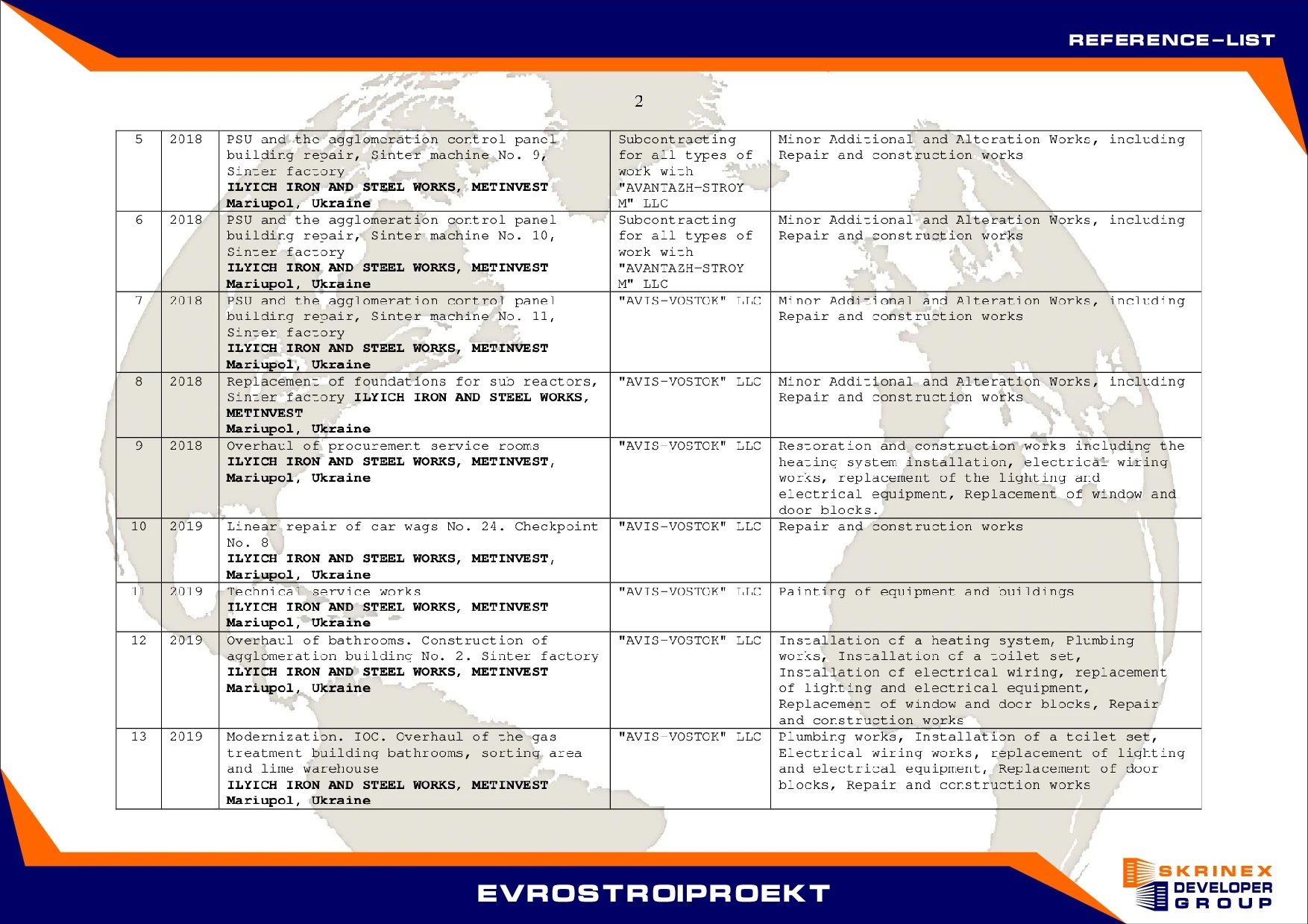

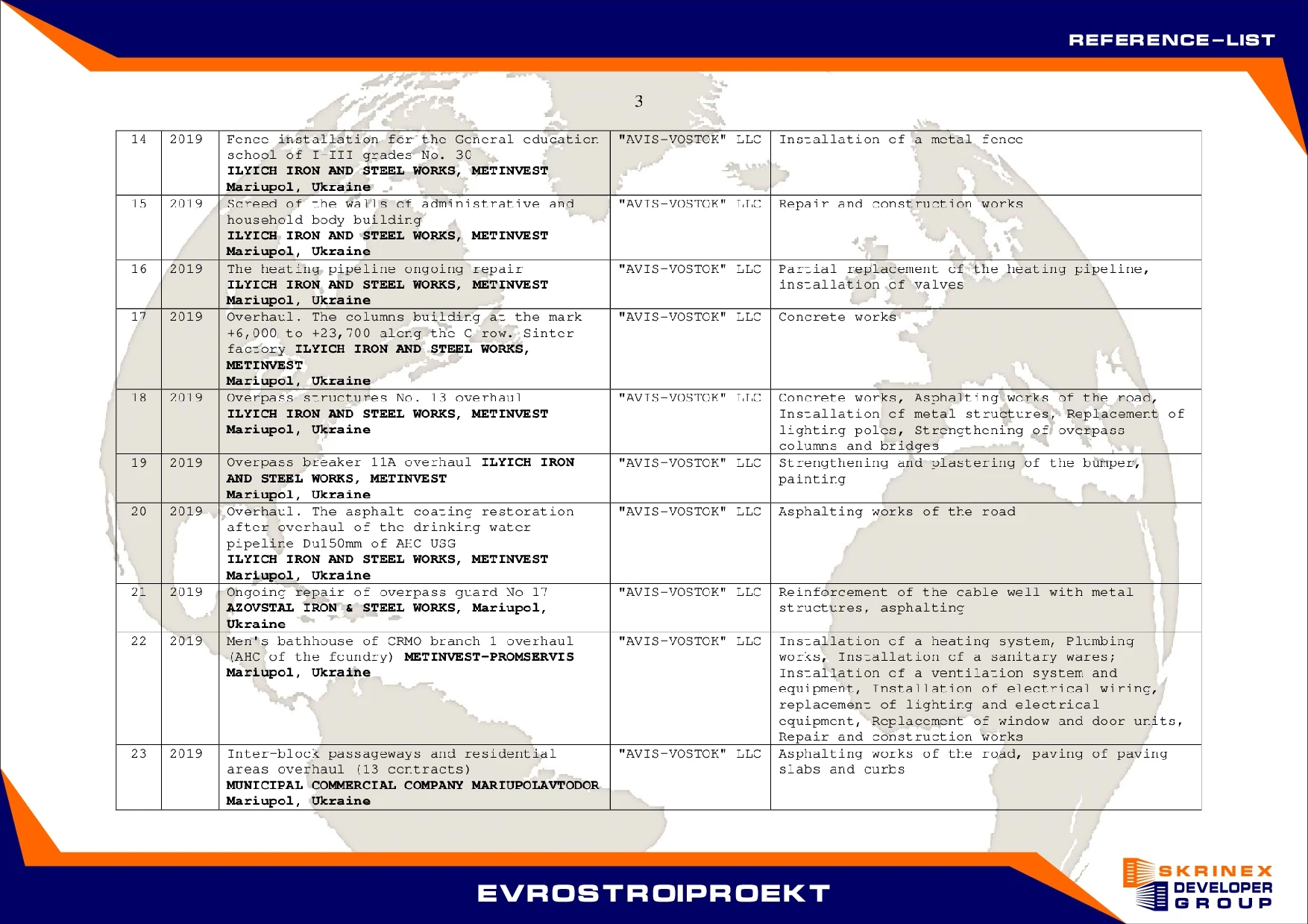

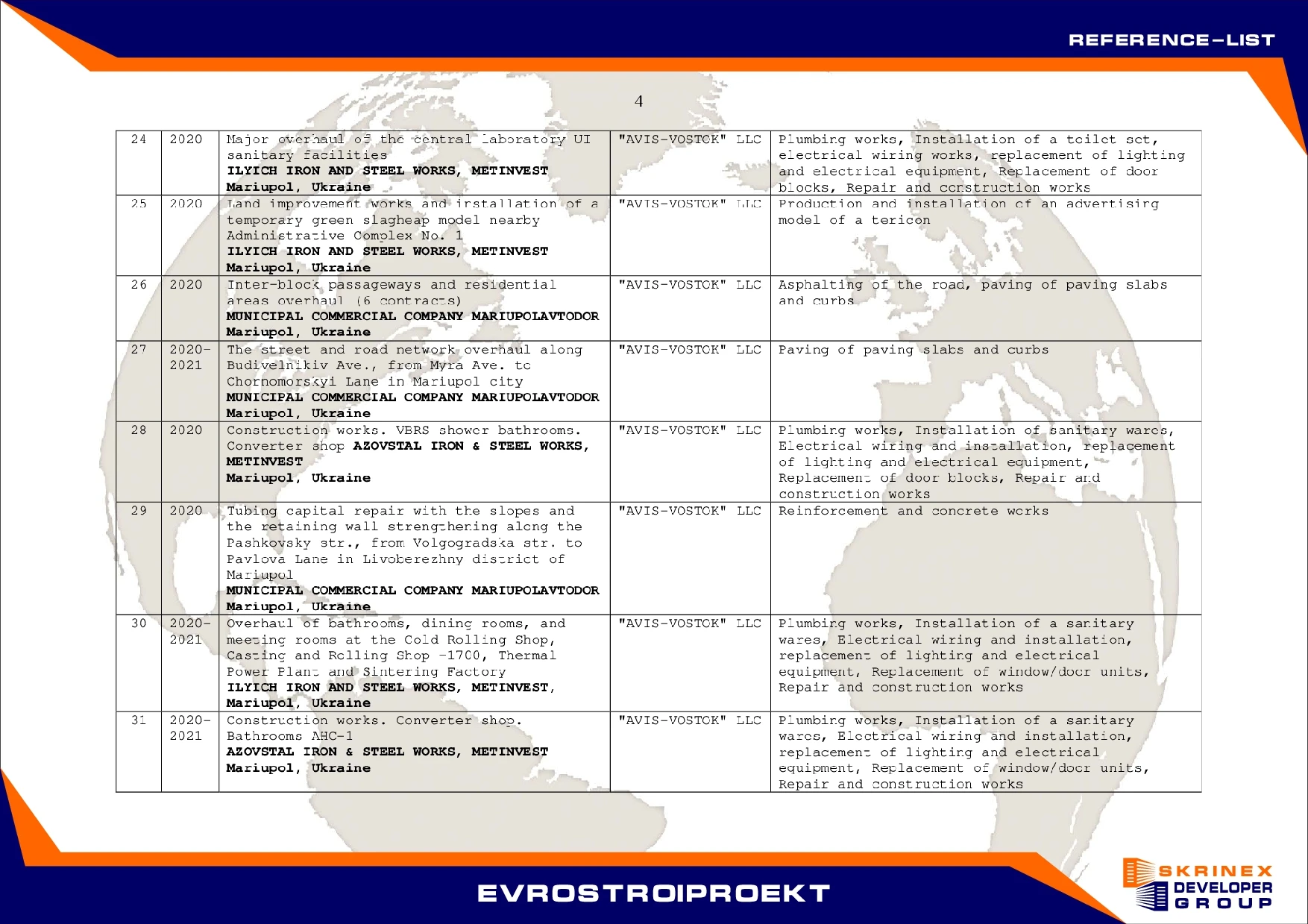

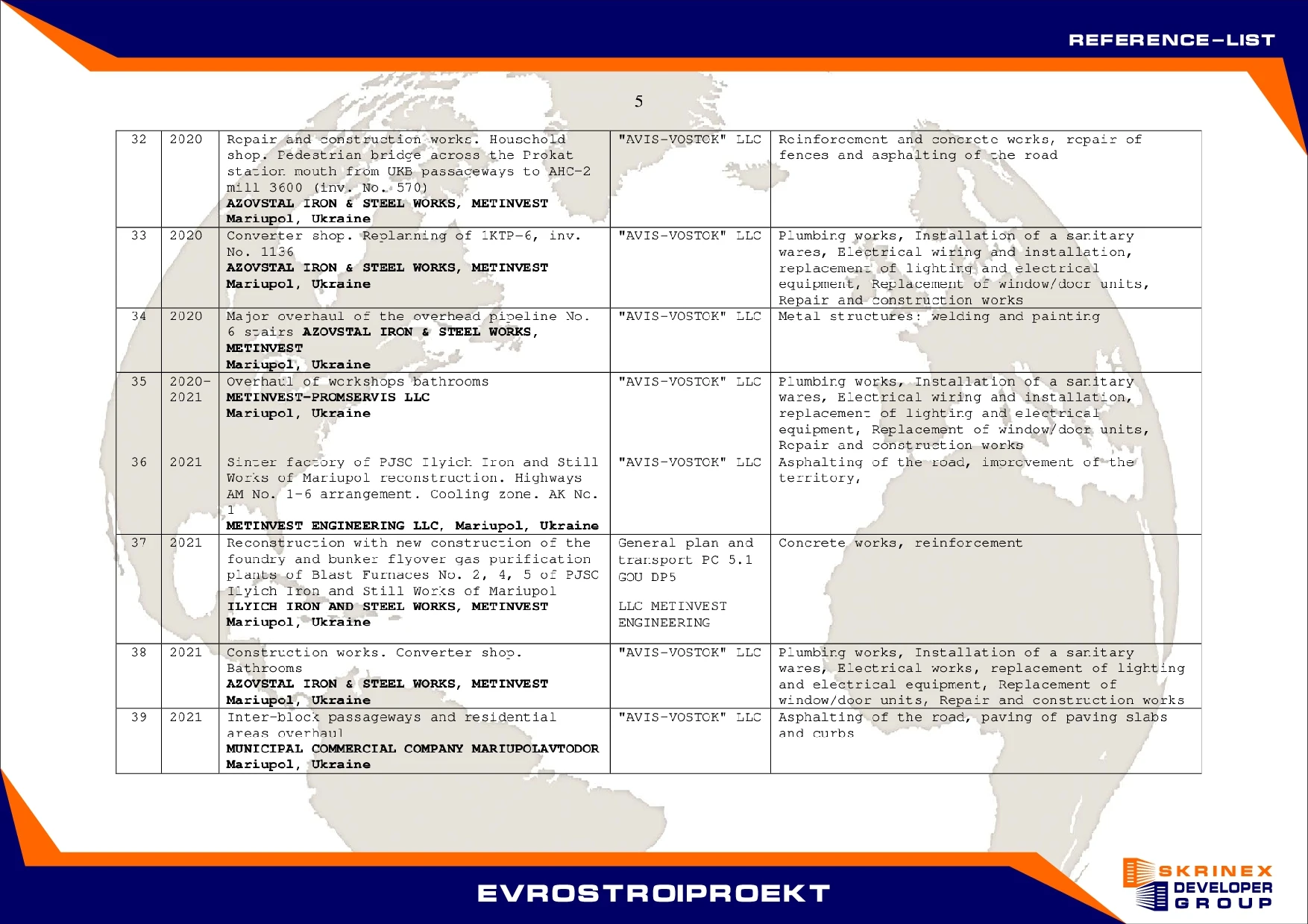

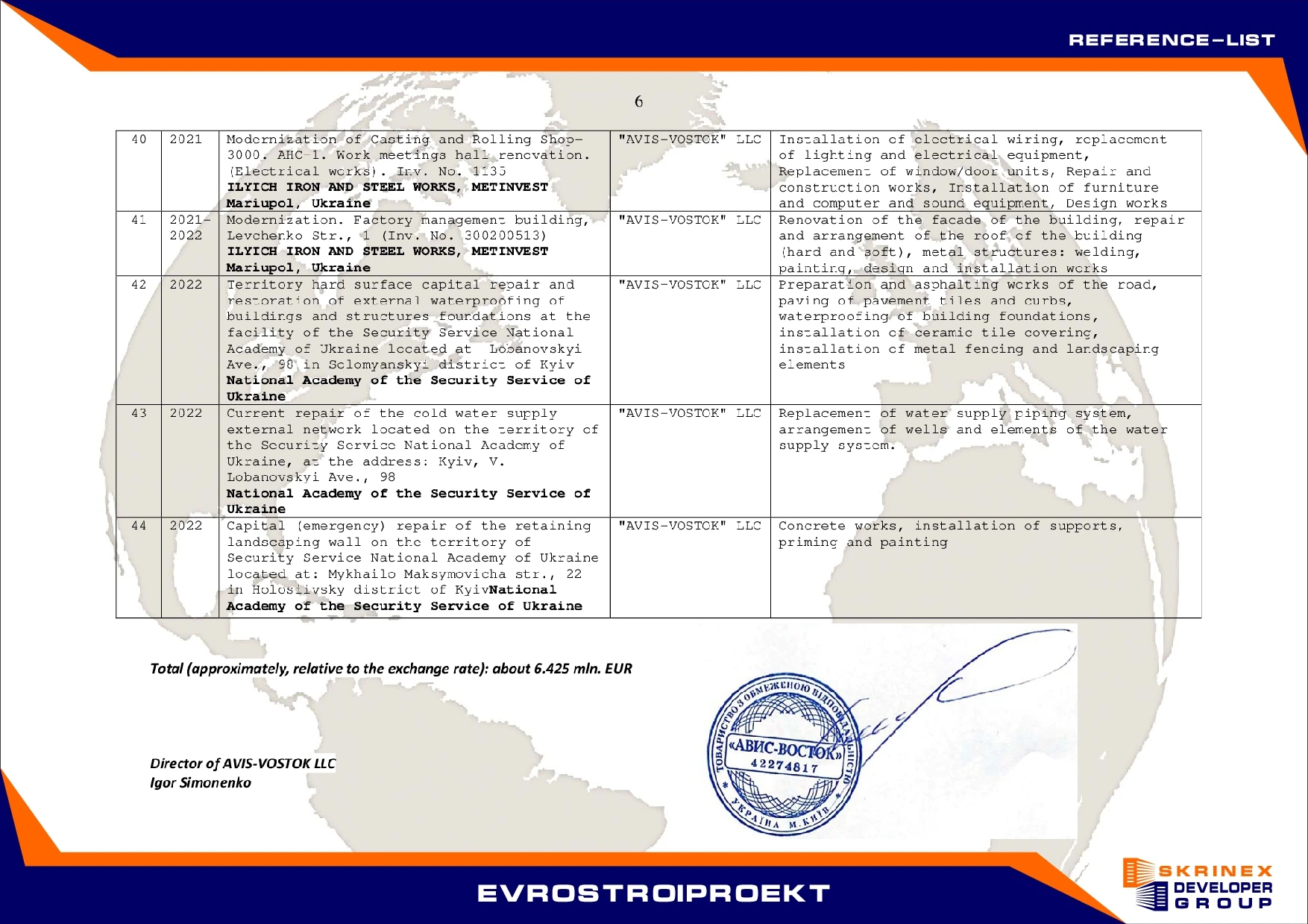

During the period from 2019 to 2022, our company's specialists completed the following works for the orders of Metinvest Holding LLC assets:

- Overhaul of PA 6738 press with a force of 630t RMTS-6 for Metinvest-MRMZ LLC.

- Overhaul of shot-blasting chamber No.1 of the foundry shop No.1 for Metinvest-MRMZ LLC, including the restoration of the DSK aspiration system.

- Repair of hydraulic cylinders for electrode lifting in the ladle furnace-converter shop of Azovstal Iron & Steel Works PJSC.

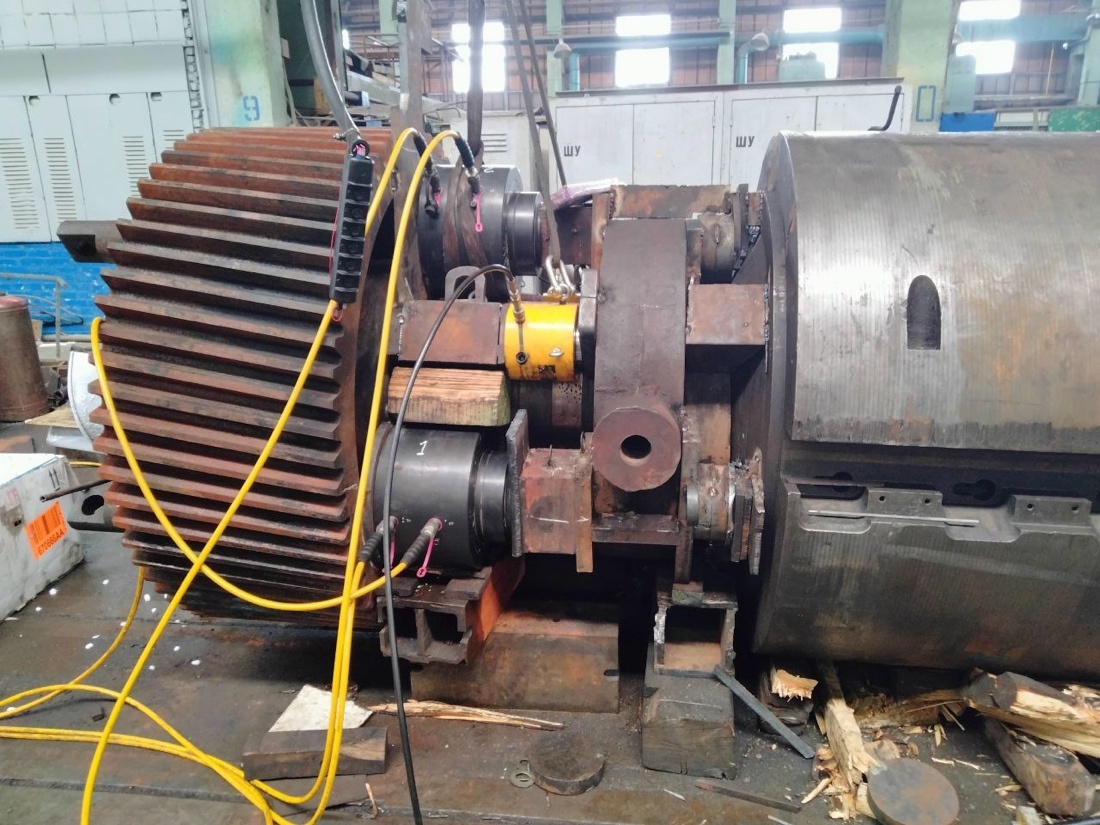

- Repair of gear unit block for rolling stand R2 LPCT-1700 of Illich Iron & Steel Works PJSC.

- Repair of the upper knife drum assembly of the APR CHP of Illich Iron & Steel Works PJSC.

- Repair and reconstruction of screw conveyors in the dust discharge system of Azovstal Iron & Steel Works PJSC.

- Overhaul of slag skimmer machine for Azovstal Iron & Steel Works PJSC.

- Installation of ladle lining scanner KS-350 in the converter shop of Azovstal Iron & Steel Works PJSC (turnkey project: working design, manufacturing and supply of materials, installation, and commissioning).

- Participation in the construction of the Continuous Casting Machine at Illich Iron & Steel Works (Building of CCM No.4, Ladle Furnace Installation, Gas Cleaning, Water Management Block, Water Tower, Transformer Substation 110/35 kV, High Voltage Line 110 kV, Slab Storage Warehouse, Railways/Highways, Compressor Station).

- Reconstruction of the LPCT-1700 rolling mill, foundation work for new equipment while the mill is in operation, installation of a reversible stand (400t) using MAMMOET lifting equipment, installation of an Intermediate Rewinding Device (COIL BOX), installation of winders, installation of roller table sections, and milling of finishing stand housings for overlays.

- Reconstruction of the sinter plant: (bag filters, conveyors, gas ducts).

Installation of the roughing stand motor for the LPCT

Installation of the rolls for the curved frame (banana) of casting strand No. 4 for the continuous casting machine (CCM)

Installation of the end fitting for the main gas duct

Installation of the bag filter ducts

Installation of the scraper conveyor

Skidding of the reversible roughing stand for the LPCT 1700

Alignment and installation of the columns and beams for the water management system of the CCM No. 4 complex at Illich Iron & Steel Works

Installation of the supporting structure for the dust collection bunker

Installation of the gas duct, beam, and saddle in the design position

Installation of a producti on line for reinforced concrete products at our own manufacturing facility

INSTALLATION OF HEAVY EQUIPMENT (laser scanner for steel ladles 350 tones)

REVERSE-ENGINEERING AND REFURBISHING OF INDUSTRIAL EQUIPMENT (DE-SLUGGING MACHINE)

REPAIR OF INDUSTRIAL CARDAN SHAFTS

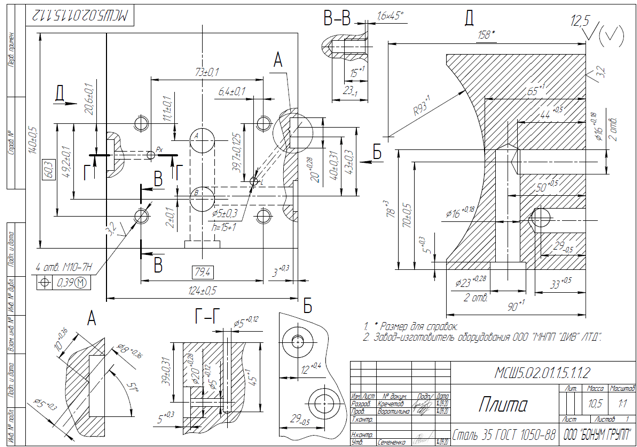

DISASSEMBLY, ASSEMBLY AND REPAIR OF HEAVY GEAR UNITS WITH HEATING, COOLING WITH DRY CO2 AND PRESSURE UP TO 1800 TONES

CAPITAL REPAIR PRESS MODEL PA6738 FORCE 630T RMC-6 LLC "METINVEST-MRMZ"

Scope of work

- Dismantling of the press, delivery to the contractor's production site.

- Disassembly of the press, preparation of a detailed and general defect list, inspection of all parts.

- Restoration of the geometric accuracy of the press's guiding surfaces.

- Inspection of the traverse movement mechanism with replacement of worn units and bearings.

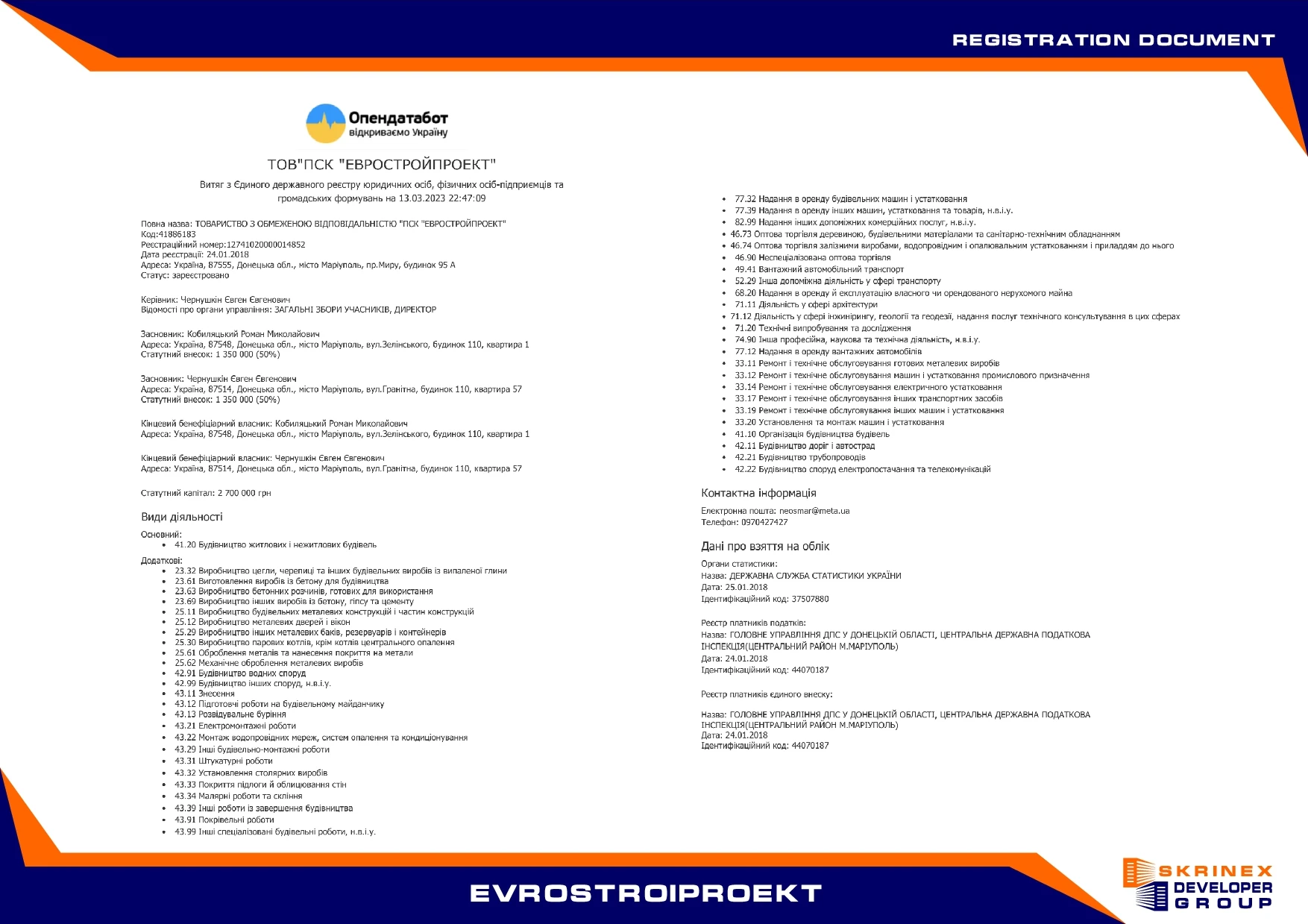

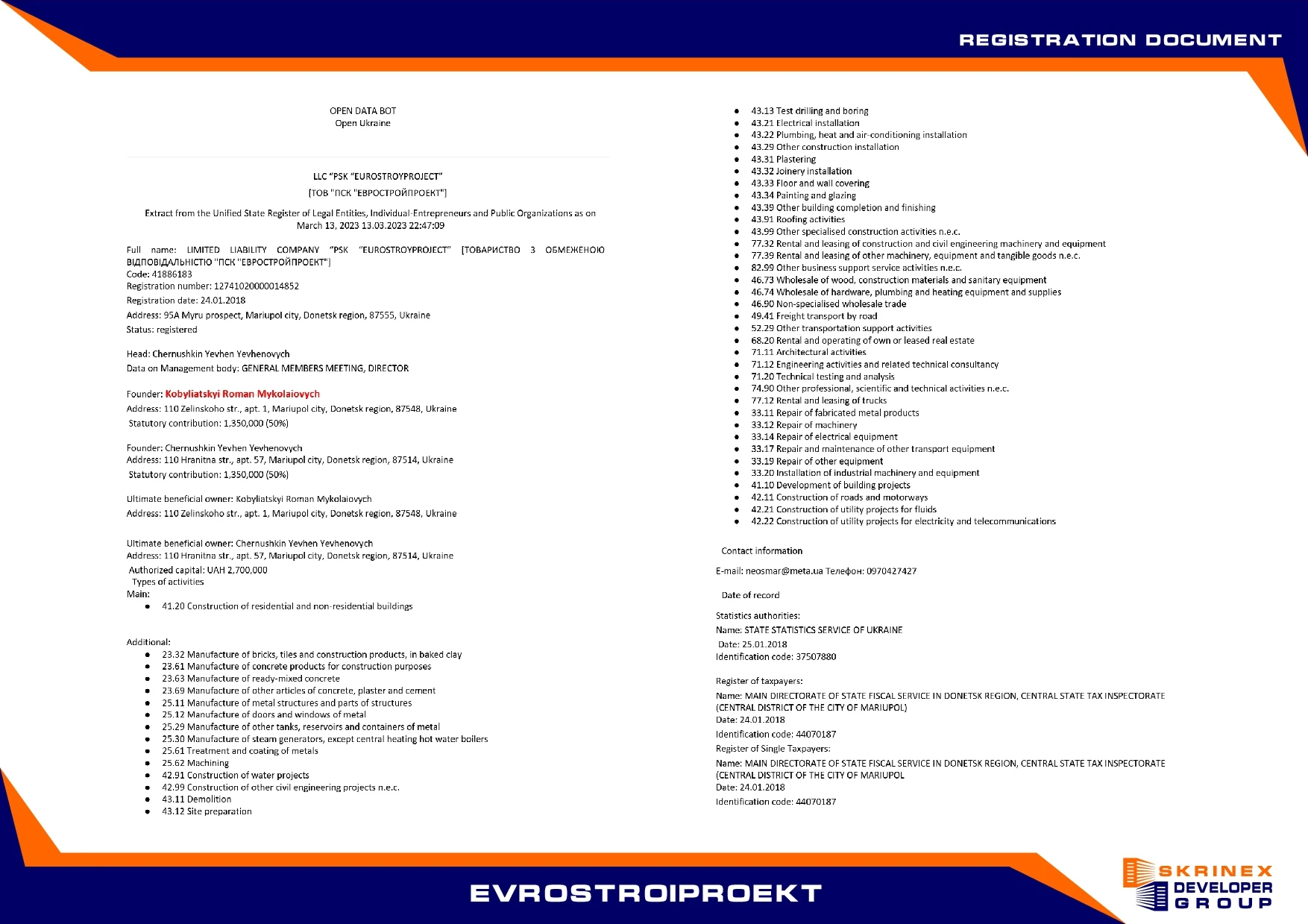

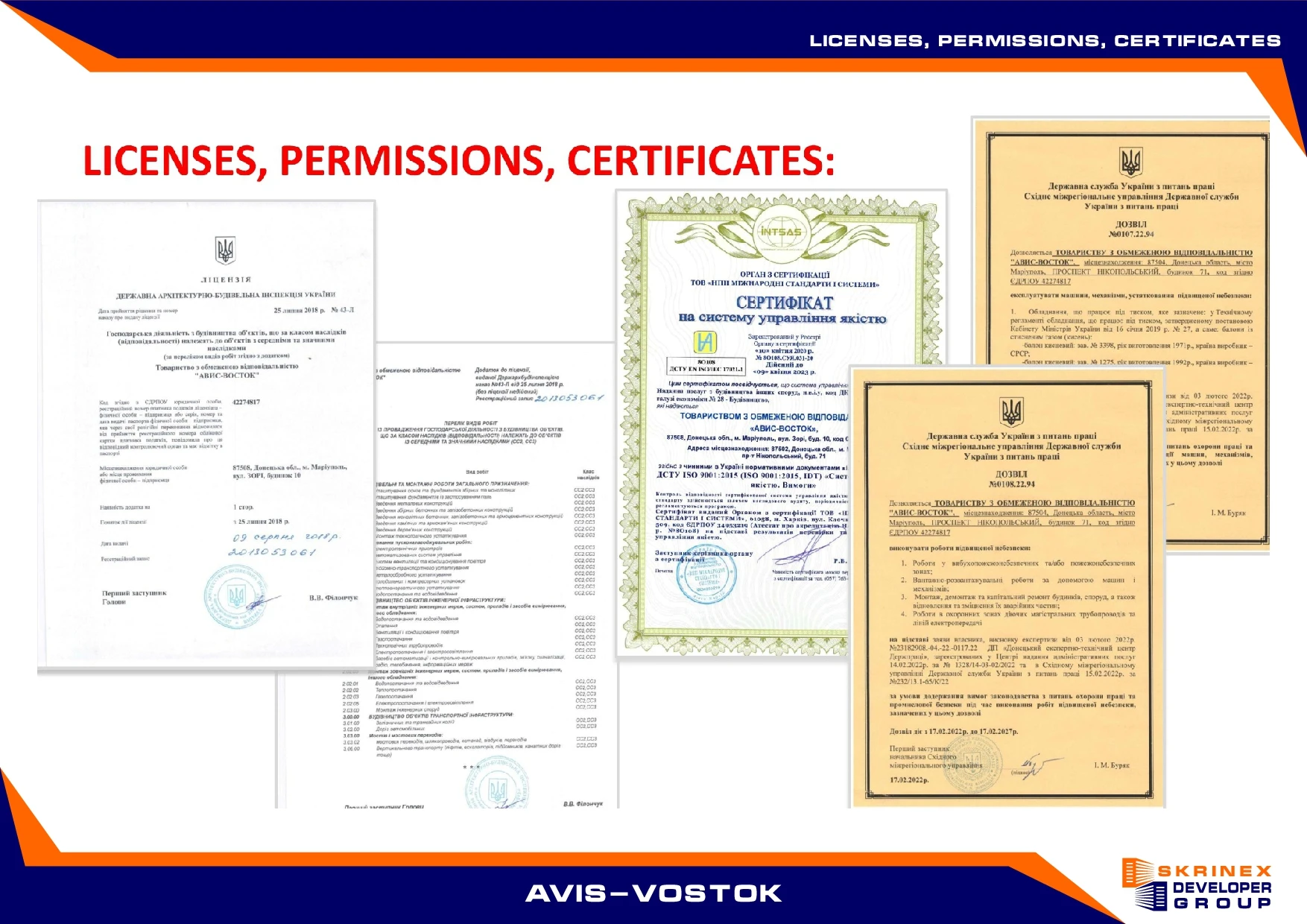

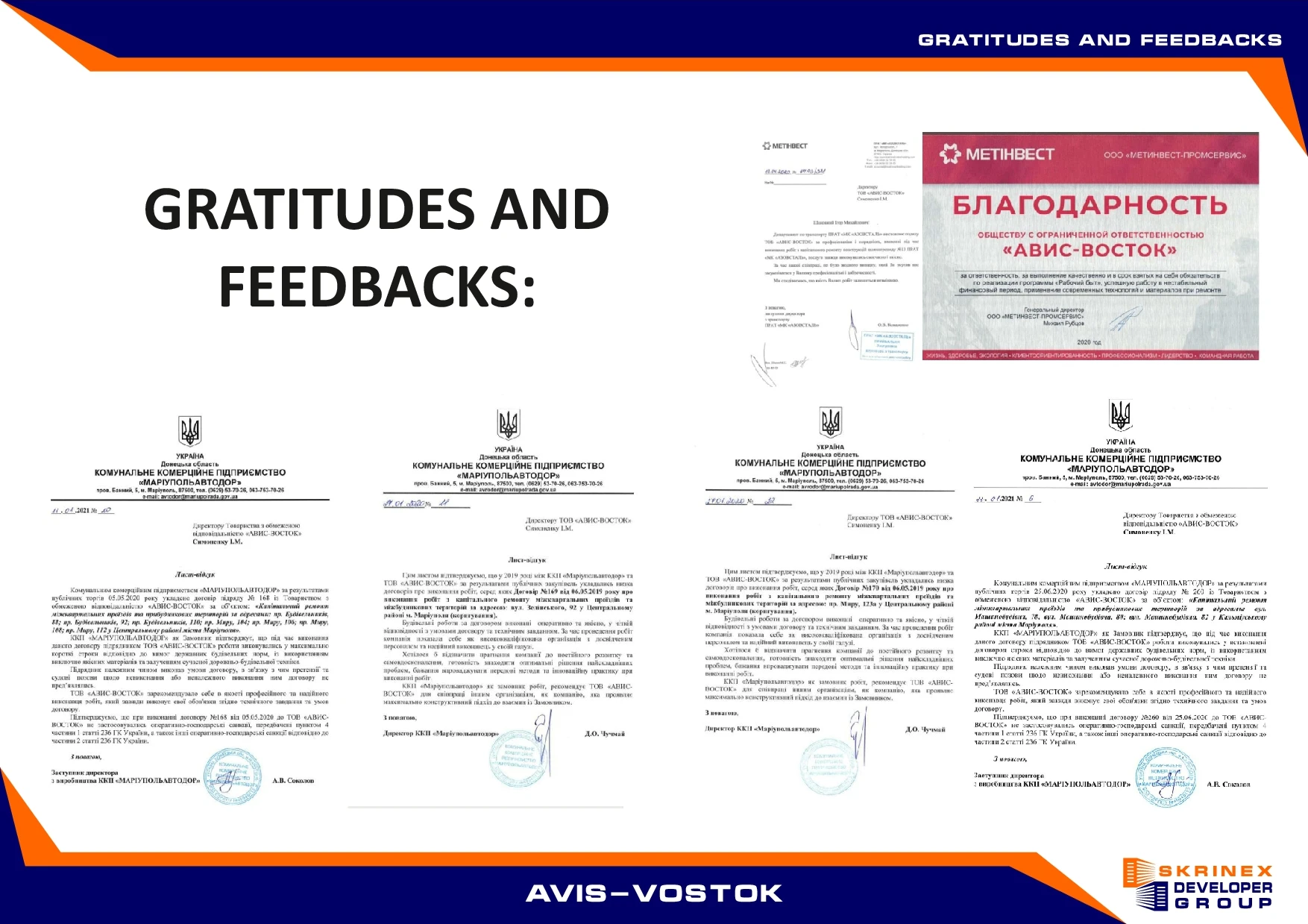

At the moment, dedicated experts of the engineering staff as well as qualified workers who performed construction and installation works in Ukraine, as social infrastructure facilities, at large metal-producing plants of the “Metinvest” group are the basis of the holding’s labor resource. We offer you more detailed information about companies whose experience, knowledge and skills, as well as labor resource, are the basis of “Skrinex Industrial”.

We offer you more detailed information about companies whose experience, knowledge and skills, as well as labor resources, are the basis of "Skrinex Developer Group".

For confidentiality reasons, the photographs of our work are not publicly available. You can view our portfolio using a special code.